Chain Conveyor Manufacturers in Pune, Suppliers and Distributors in Pune

Synergy Global Engineering, leading chain conveyor manufacturers, suppliers, and distributors in Pune, are providing the best and newest technological chain conveyors that are used for transporting different kinds of materials over longer distances.

Premium Chain Conveyor Manufacturers in Pune:

These are connected with high-quality chains for smooth handling of materials. Various types of new technological sensors and advanced types of automation help with increasing the performance. Let’s check out our various types of chain conveyors, their benefits, and their applications also!

Various Types of Chain Conveyors:

Being the best chain conveyor suppliers in Pune we provide multiple types of conveyors that give maximum performance, such as:

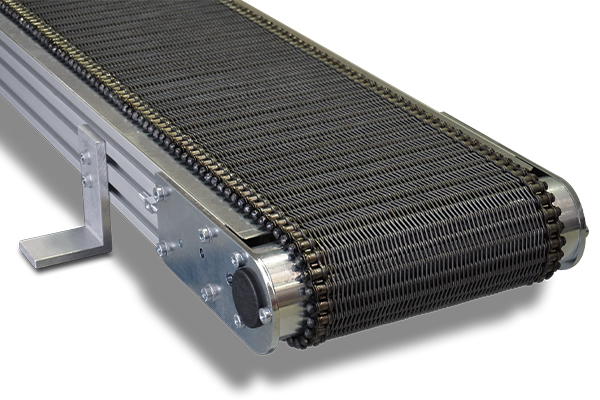

- Slat Conveyors: These conveyors have different kinds of slats that are made with metal, plastic, and wood for improving grip. We have used strong quality materials in these slat conveyors for improving the performance and being able to handle heavy kinds of materials. Our modern slat conveyors use advanced motors that consume less energy, which helps save on costs. They also have modular parts, making it simple to customize and replace components as needed. In the automotive industry, these conveyors are often used to move heavy car parts and components quickly and efficiently.

- Overhead Conveyors: Overhead conveyors hang materials or products above the workspace, which helps save floor space. They are typically powered by chains or belts and can be adjusted to fit different layouts and specific needs. Modern overhead conveyors have smaller, energy-saving drive systems with the ability to change speeds as needed. They also include features that reduce vibrations and noise, which helps protect the system and prolong its lifespan. In electronics factories, overhead conveyors are useful for moving delicate components that require careful handling to avoid damage.

- Incline/Decline Chain Conveyors: Incline and decline belt conveyors are designed to move materials up or down at different angles. The belts can be made of rubber, plastic, or metal and can handle a variety of products, no matter their shape or size. These conveyors often have special anti-skid belts that prevent items from slipping, ensuring safety during transport. In food processing plants, they are commonly used to move food items efficiently between different levels of the processing areas.

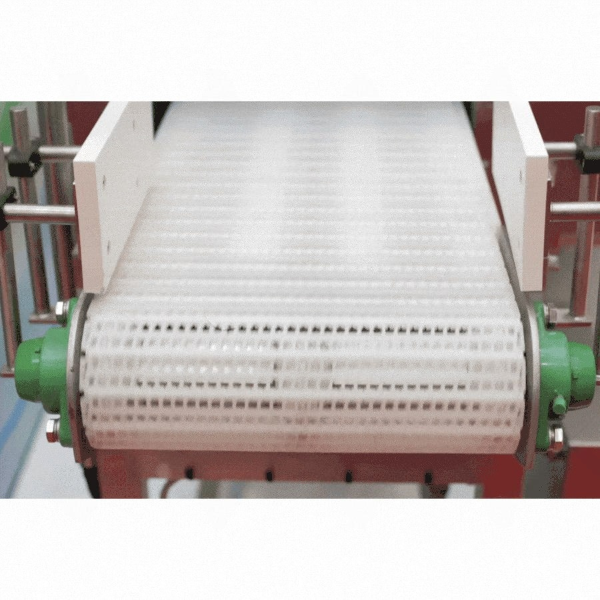

- Modular Chain Conveyors: These conveyors have the interlocking plastic or metal modulus, which has better flexibility and durability. Modern conveyor systems are built to handle tough materials, with better resistance to chemicals, heat, and wear, which means they last longer and perform reliably. They often have a modular design with parts that can be easily replaced, maintained, and customized. These systems can also work seamlessly with robots, sensors, and automated technologies, making operations smoother and more efficient. In food and beverage processing, plastic modules are commonly used to meet strict hygiene standards.

Technical Features:

Being chain conveyor distributors in Pune, our products are equipped with various advanced features. for more clarification about our chain conveyor and its types, we have mentioned below a technical sheet such as:

| Attribute | Slat Conveyors | Overhead Conveyors | Incline/Decline Belt Conveyors | Modular Belt Conveyors |

|---|---|---|---|---|

| Drive Type | Mechanical chain drive | Electric or motor-driven chain system | Motorized drive, friction rollers | Modular chain drive |

| Conveyor Speed | 5 - 30 meters/min | 10 - 40 meters/min | 5 - 30 meters/min | 5 - 20 meters/min |

| Load Capacity | Up to 5000 kg | Up to 1000 kg | Up to 3000 kg | Up to 2000 kg |

| Chain Material | Steel or stainless steel | Steel or coated materials | Stainless steel, heat-resistant belts | Plastic, stainless steel chain |

| Frame Material | Carbon Steel, Stainless Steel | Carbon Steel, Coated Steel | Carbon Steel, Stainless Steel | Modular plastics, stainless steel |

| Belt Width / Chain Pitch | 300 - 1000 mm | Varies based on the system | 300 - 1200 mm | 300 - 1000 mm |

| Angle of Operation | Horizontal | Vertical or inclined | Up to 45 degrees | Horizontal and inclined |

| Temperature Range | -20°C to 300°C | Up to 400°C | -20°C to 350°C | -10°C to 60°C |

| Energy Efficiency | High | Medium | Medium | High |

| Noise Level | Moderate | High (due to overhead systems) | Moderate | Low |

| Maintenance Requirements | Periodic chain tension adjustments | Periodic lubrication & motor checks | Belt wear checks, incline alignment | Modular components, replaceable belts |

Features and Benefits of Using Our Chain Conveyor in Pune:

Being the best chain conveyor manufacturers in Pune, all our types of chain conveyors are filled with the latest technological updates and give numerous benefits such as:

- Efficient Material Handling: Handling materials efficiently helps save money on transportation by using less energy and reducing overall costs. Whether you use chain conveyors or roller conveyors, they keep production running faster and smoother without interruptions. Moreover, sturdy conveyor systems improve workplace safety by minimizing the need for manual handling and lowering the risk of injuries.

- IoT Integration: All types of chain conveyors are connected with new technological sensors and devices that can help with increasing performance. These updated latest technologies give real-time updates and monitoring of each and every task.

- Advanced Chain Materials: We have used strong and pure forms of raw materials in these chain conveyors, such as stainless steel and cast iron. These materials help machines to resist any kind of corrosion and higher temperature.

- Wireless and Remote Control Integration: Remote monitoring and operation through wireless communication and central control panels make it easier and safer for employees to manage the system from outside the facility. It also allows for quick fixes and adjustments, reducing downtime and keeping operations running smoothly.

Applications of our Chain Conveyors:

One of the dominant chain conveyor manufacturers and suppliers in Pune, these all types of conveyors are used in multiple types of industries, following are the applications of chain conveyor in Pune:

- Automotive Industry: Used to transport car parts and assemblies during manufacturing and assembly lines.

- Food & Beverage Industry: Ideal for moving food products and beverages with hygiene and durability considerations.

- Packaging Industry: Employed to transport and align boxes, bottles, and packaged goods on assembly lines.

- Pharmaceutical Industry: Suitable for handling bottles, containers, and blister packs with strict hygiene requirements.

- Logistics & Warehousing: Used to move packages and materials efficiently across warehouses and distribution centers.

Being the best chain conveyor manufacturers in Pune, suppliers and distributors in Pune, we at Synergy Global Engineering are presenting the new technological chain conveyors that are highly in demand from various types of industrial sectors due to their working mechanism. These are made with accurate engineering techniques and pure forms of materials for increasing productivity. Contact us today for more information!