Screw Feeder Manufacturers in Pune, Suppliers and Distributors in Pune

Pioneering innovation in material handling, Synergy Global Engineering, the former screw feeder manufacturers in Pune, suppliers, and distributors in Pune, are providing the best and unique types of screw feeders, which are commonly used for controlling the flow of bulk materials into a system at a specific rate.

Leading Screw Feeder Manufacturers in Pune for Precision Engineering:

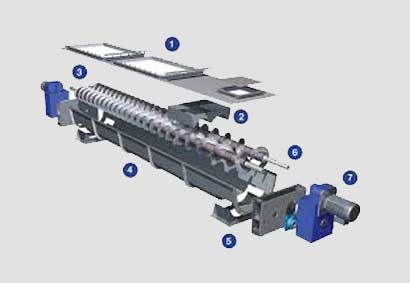

These are mounted at the base of a hopper or bin and used to handle the materials with a specific amount of quantity. It has multiple types of features, such as accurate feeding techniques, versatility, and ease of maintenance. These are highly demanding from multiple types of industries. Below, we have mentioned various types of our screw feeders, their benefits, and applications also!

Types of Our Screw Feeders:

As leading screw feeder suppliers in Pune, we are providing multiple types of screw feeders, and each one is made with strong quality of materials. Here we have listed some types, such as:

- Inclined Screw Feeders: Our inclined screw feeders are specially designed to transport bulk amounts of materials in an upward or inclined direction. We have used new technological updates, such as variable speed drives, that are used in these screw conveyors for adjusting speed dynamically. Also, the advanced materials in these machines, such as stainless steel or cast iron, help maintain the performance over a longer period of time.

- Shaftless Screw Feeders: Shaftless screw feeders don’t have a central shaft, which helps prevent clogging and reduces wear and tear. This makes them perfect for handling materials that are sticky, abrasive, or viscous. Many of these feeders now come with modular designs, making them easier to install and replace, saving both time and money.

- Live Bottom Screw Feeders: These live bottom screw feeders have the rotating screws that continuously discharge materials from bins or silos while maintaining a continuous flow. These systems are designed to maintain a smooth, predictable flow, which is crucial for batching and processing. Advanced models use precision load cells to measure the material flow accurately, ensuring precise control and reliable operation.

- Gravimetric Feeders: Gravimetric feeders directly weigh materials to ensure precise and accurate dispensing, making them perfect for batching and blending tasks. They work by measuring the weight of the material, providing consistent and reliable control. These feeders are often connected to systems like SCADA and PLC for real-time monitoring and control. In the plastics industry, they are widely used to feed resins and additives with precision during compounding.

Technical Specifications:

As screw feeder manufacturers and suppliers in Pune, we have mentioned below a technical sheet of our Screw Feeder such as:

| Parameter | Inclined Screw Feeders | Shaftless Screw Feeders | Live Bottom Screw Feeders | Gravimetric Feeders |

|---|---|---|---|---|

| Material Type & Flow | Free-flowing and sticky | Sticky, fibrous, wet | Cohesive, hard-to-flow | Powders, granules, pellets |

| Inclination Angle | Up to 60° | Horizontal/Inclined | Horizontal/Inclined | Horizontal |

| Capacity (m³/h) | 1–250 | 0.5–150 | 1–100 | 0.1–30 |

| Power Requirement (kW) | 0.5–50 | 0.3–20 | 1–30 | 0.5–10 |

| Material of Construction | SS304, SS316, Carbon Steel | SS304, Duplex Steel | SS316, Carbon Steel | SS304, SS316, Titanium |

| Accuracy | ±2–5% | ±2–4% | ±3–6% | ±0.5–1% |

| Special Features | Compact design, requires higher power at steep angles. | Open design, higher torque, reduced clogging. | Multiple screws to prevent bridging and arching of materials. | Continuous weight monitoring with load cells. |

| Maximum Capacity (m³/h) | 250 | 150 | 100 | 30 |

| Inclination Angle (°) | 0–60 | 0–30 | 0–20 | 0 |

| Power Range (kW) | 0.5–50 | 0.3–20 | 1–30 | 0.5–10 |

| Length Range (m) | 2–30 | 2–25 | 2–15 | 0.5–10 |

| Screw Diameter (mm) | 100–800 | 150–600 | 150–600 | 50–300 |

| Accuracy (%) | ±2–5 | ±2–4 | ±3–6 | ±0.5–1 |

Features and Benefits of Using Our Screw Feeder in Pune:

Being the former screw feeder distributors in Pune, all types of screw feeders are made with the latest technological features and give major benefits such as:

- Advanced Automation Integration: Screw feeders can be connected to control systems like PLCs (Programmable Logic Controllers) and SCADA (Supervisory Control and Data Acquisition) to ensure better control and monitoring of material feeding processes. This setup allows operators to make real-time adjustments, track performance, and maintain a more efficient and reliable operation.

- Robust Construction: aThese are made from strong materials like stainless steel and cast iron, which help them last a long time. They are built to handle tough conditions and are resistant to wear, rust, and damage. This means they can operate reliably without frequent repairs, even in challenging environments.bcd

- Energy-Efficient Motors: Variable Frequency Drives (VFDs) help save energy by adjusting the motor speed according to the actual needs of the system. The motor control automatically changes power usage based on the material load and the required speed, ensuring the system operates more efficiently. This reduces energy costs, minimizes wear and tear, and helps maintain a more reliable and long-lasting operation.

Applications of our Screw Feeders:

One of the best screw feeder suppliers in Pune, these all types of screw feeders are majorly used in multiple types of industries, the following are the applications of screw feeder in Pune.

- Food processing for powders and granular materials

- Chemical industry bulk powder and material handling

- Cement plant feeding system for bulk materials

- Pharmaceutical metering and dispensing of ingredients efficiently

- Plastic processing, transport, and feeding of granules

- Agriculture handling seeds, grains, and feed materials

- Mining, transporting, and feeding ore and gravel

- Recycling plants distributing and transporting materials efficiently

- Wood processing feeding sawdust and wood materials

- Concrete batching system handling cement and aggregates

Being the best screw feeder manufacturers in Pune, suppliers, and distributors in Pune, we at Synergy Global Engineering are providing the best types of screw feeders. These are made with strong and pure quality materials and connected with the latest technological sensors. Each type of screw feeder has different types of features and is able to be used in every industrial sector. Contact us today for more information!